The Future of Automation — 2010

The first of the year is traditionally a time to reflect on big picture trends. In their January 2010 issue, Automation World’s Editor Gary Mintchell brings together “technologists, Users, and Pundits” to “Ponder the Future of Automation” You can read about it here at; Automation World.

Automation World’s Editor Gary Mintchell brings together “technologists, Users, and Pundits” to “Ponder the Future of Automation” You can read about it here at; Automation World.

To quote the first few sentences of “the State of Innovation” is to capture the essence of Automation and why it is so appealing.

“Changing approaches now can offer a foundation for future prosperity. The technology business has always been the world of cool ideas. How can you do something faster or easier, or make a whole lot more of something with little or no extra effort?”

Appealing to some but not others. There is a shortage of qualified individuals and a shortage of innovation according to Pundits Jim Pinto and Charlie Gifford that are covered in the article.

Interesting takeaways were to do with the turmoil in the indusrty. Talking “Ten Years Out” many of the ideas springing up today are ten years out in implementation. The stoggyness of the industry is cited as a reason.

Time and time again I’m reminded of the gaps in the Automation Industry. There are the functional gaps that exist between appliances, the protocols, and the applications; in essence the “work” of the Automation industry. There are gaps in the structure of the industry as well; a lack of standards, a lack of innovation , a lack of outward understanding, and a mypotic view by the big players in the game. All too much here for this post. Perhaps I’ll tackle it soon.

Productize your Service or Servicize your Product?

It seems those business models are moving in opposite directions these days. The destabilizing force of unlimited information and data is wreaking havoc with business inertia.

Inertia; because a company set on a course tends to want to stay on that course. Once it chooses to solve a customer problem in one way it channels its resources into it, and there is cost with reengineering the chosen approach.

In engineering circles, productizing your service makes it easier to buy. Customers have a better idea on what they are buying; a product that has more easily defined goals and functionality. Engineering services are sometimes more difficult to grasp as they are deployed as a one-off solution. For many applications, there is no way around it. The issue with engineering companies it that it leads to difficulty in growing the scale of the business. The level of professional expertise is finite in the number of experts employed.

Engineering talent is often the limiting factor. If your company can take that know-how and package it into a product, scalability is easier.

Once you have a product, adding services makes it more valuable. Sometimes so much so that the product is given away at a loss or even free. Look at the costs of phones. Since its introduction in 2007 the iPhone’s price has dropped like a rock, the service however is the business model for Apple.

The introduction of the iPad last week is a good example of a company exploiting a proven platform to squeeze more hardware sales, and open up new service possibilities. The reviews are coming in fast and furoius but I’m reading that it’s just a really big iPhone. The key here is that it really is more than that. Because of the iPhones’s size, many applications didn’t work well on the small sceen.

Now that they have an updated platform, with the iPad, more services will be created to take advantage of the size. Apple is taking another run at the service-product-service cycle.

The dilemma today is the rapidly accelerating rate of change. By the time you get your project off the ground the market, it’s quite likely that the worlds has moved on.

Along comes a disruptive innovation open source to change the game your company’s committed to; proprietary Windows to Linux, MS office to Open Office, Servers to Cloud Computing. It is an increasingly clear fact that whatever strategy chosen, a business needs to keep an eye out for competitive threats to a business model. Apple’s new iPad is a complemenmtary product that extends the brand and the base technology from the iPhone.

Business-wise, it should be a winner.

Learning From Baseball Stats

I don’t profess to be a sports nut but I like a good game. Call me fair-weather fan. I usually get caught up in the excitement when there is something big happening; playoffs, a record-breaking milestone, the home team doing well. I caught CBS’s 60 Minutes a while back on a story that aired originally in 2008. It was about Bill James, a man who was a fan and statistician that changed the management methods of the Boston Red Sox for the better.

Bill James was an unlikely source of information for baseball leaders to make decisions; not athletic but  an outsider and pure observer. The Boston Red Sox utilized his analysis to better manage the game and create a wining season.

an outsider and pure observer. The Boston Red Sox utilized his analysis to better manage the game and create a wining season.

I just heard about the story, but since it aired last year others have blogged about it. The opinions I found are interesting. All of the blogs I researched were opinions about the individual statistics that James relies on and the blogger’s opinion to their usefulness. The talk centered on the game of baseball and was objectified from a fan’s perspective.

I got a different impression. What was fascinating is the numbers themselves, and how they serve to provide a different perspective driving the business of baseball. Being a hard-core fan requires some discipline to know those little nuggets about a player and his behavior. I won’t get into the details here but the act of following a situation such as a baseball game, series, rivalry, or season has its merits. The important take away that I got was again the idea that what statistics get measured tend to improve. Fans can look at the metrics to help them enjoy the game more. The teams themselves are learning that measuring activity in different ways, leads to a concentration on the right activity, and that leads to success.

Watching the episode, there are some great parallels to common mistakes made in business and manufacturing. Dashboards are set up with the ‘proven’ key performance indicators and strategy based on metrics can set a company off course. There needs to be a continuing re-evaluation of the key things you follow, and a quest for more sources of data.

Sport is recreational and entertaining yet it has the ability to galvanize much of modern culture’s happenings in an observable way. Sport is a good metaphor for competition and passion and human trials that sometimes parallel everyday life. There can be a lot to learn if you focus on the objective aspects.

Nevertheless, if you feel like painting your face and screaming in support, have a good time.

The Future of Work

From the CNBC Series ” The Business Of Innovation” Rethinking Work:

“Despite enormous advances in technology, our workplaces are not nearly as efficient as they could be: each week, more than 40% of employees use incorrect information to make decisions, thereby wasting time and resources. The third episode of The Business of Innovation explores how “wiser work” can lead businesses and governments to prosper”

While the subject matter meandered off topic to transportation, the program provides a good basis for thinking about the changing nature of work.

There is an imbalance in the use of technology in personal lives vs corporate environments. This imbalance has increased in recent years. Individuals have better information sharing tools at their reach than companies do. Facebook, Twitter, linkedin provide social networking opportunities never seen before. In factories, decisions made years ago still handcuff companies. Old ideas still work as the accountants weigh the cost of new technology vs the incremental savings in costs when they should be measuring the increase in productivity.

If there was a low cost simple way to take existing technology to a new level in factories, companies would benefit from new flexibility without having to dispense with past capital investments.

The current state of the factory is surprisingly backward in comparison. Systems and processes are very much like they were years ago when first implemented. Many solutions are crafted as “work arounds” providing the solution in a second rate way.

Every Book You Have Ever Wanted

Throughout history there’s been plenty written on every subject. Much of it is either out of print or hard to find. Coupling technology with information is yielding a new seemingly low cost effective way to blow the dust off the covers of these old texts.

It’s happening on a couple of fronts. Google has been digitizing classics for some time and has recently entered into an agreement with the makers of an automated book binding machine. Another effort is known as the Guttenberg project

On 9/28/2009 Alan Reiter published a story about a new automated distribution model for book sales.

http://www.internetevolution.com/author.asp?section_id=526&doc_id=182325&

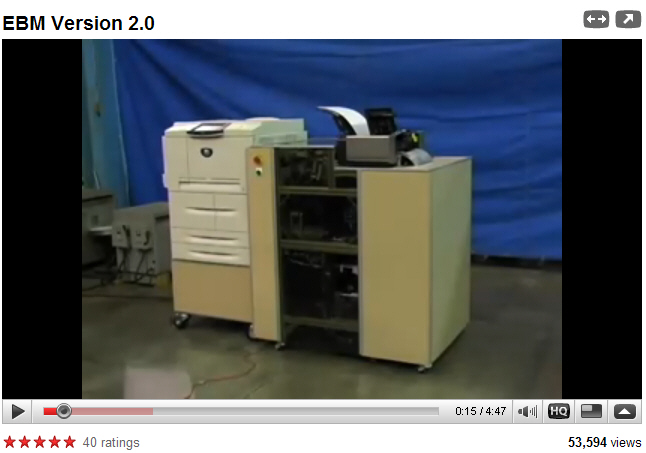

In it he introduces the Espresso Book Machine that is an on demand publishing outlet.

When you consider the print on demand business model it’s really an example of distributed manufacturing.

Each automated machine is its own manufacturing plant churning out a book one at a time from a digital library of millions of titles. Compare the physical inventory of finished books to the raw materials inventory of ink and paper and you’ll get the idea. It’s far more efficient to carry raw materials that can be quickly manufactured into what is usually held in finished goods inventory. The throughput matches the demand.

What’s making the model viable is the flexibility of the medium. Hard copy books are just not as portable as the information they contain. Digitizing them also makes them more useful. Digital editions are searchable and can be far more useful. Developing semantic search technologies are making search across volumes possible.

Automation combined with the flexibility of information makes this possible.

The Internet of Things

Call it M2M (Machine to Machine) Smart Services, the Embedded Universe, or whatever you like; it’s nice to see a pull out section in this issue of Information Week Magazine (September 7 2009).

The Internet of Things Handbook Written by Amy Rogers Nazarov

It’s a good primer on one of the next evolving branches of the interconnectivity of everything we call the internet and beyond. With the emphasis on social networking applications such as Facebook, Linkedin, Twitter, MySpace, and many others it’s encouraging to see some mainstream press on the other internet where people are not as involved as the machines themselves.

The social networking trend shows that the world has definitely embraced Web 2.0. Now make way for Web 3.0. It is the internet of data; specifically Linked Data. The “handbook” doesn’t cover it but a very good overview was given by Tim Berners-Lee this year at a TED Talk.

Relating the internet of things to the idea of linked data gives rise to Web 3.0. The Information Week article is good but when you put it in the context of how Tim Berners-Lee explains the net evolution of the web it truly is a powerful future.

Here is a section of links mentioned in the article that expand on the “handbook’s” ideas. Some of the “Information Week” links were re-directs to the Internet Evolution WebPages; I’ve included the original links from that site.

We Are Smart Dust, we Are Golden…

http://www.informationweek.com/1240/ie/dust

http://www.internetevolution.com/author.asp?section_id=526&doc_id=152005

Why the Internet of Things’ is ready for Prime Time

http://www.informationweek.com/1240/ie/internet

http://www.internetevolution.com/author.asp?section_id=697&doc_id=170349

We Need Digital Transformation Not Just broadband

http://www.informationweek.com/1240/ie/transform

http://www.internetevolution.com/author.asp?section_id=757&doc_id=175793

Next Up For IT: Making Sense of the Data Glut

http://www.informationweek.com/1240/ie/data

http://www.internetevolution.com/author.asp?section_id=625&doc_id=176181

IT Connects The Internet Of Things

http://www.informationweek.com/1240/ie/connect

http://www.internetevolution.com/author.asp?section_id=625&doc_id=176477

Manufacturing Innovation

Jim Pinto recently commented on his “Pinto’s Points” Blog on future trends in manufacturing:

http://jimpinto.com/enews/25aug2009.html

Quoting from Jim’s August 25th Newsletter;

We must recognize that major parts of the economy – government, banking, insurance, health care, consumer services – use physical wealth, but do not create it. Financial services now comprise 45% of earnings of companies on the S&P 500 index, up from 10% just a quarter-century earlier.

Manufacturing is a primary wealth-producing sector and historically is responsible for this country’s relatively high standard of living compared to other countries. Manufacturing has now declined to about 11% of America’s GNP. The continued decline is ominous.

The Society of Manufacturing Engineers (SME) has an initiative that identifies emerging technologies that are making a positive impact on manufacturing. SME’s Manufacturing Enterprise Council collaboratively selected five “innovations that could change the way you manufacture”:

- Direct Digital Manufacturing (DDM): Use of additive fabrication processes; manufacturing components layer by layer, direct from 3D digital data, without machining, molding or casting.

- Ultra capacitors: Electrochemical capacitors that have an unusually high energy density and provide significantly more storage power, with unparalleled life span.

- Self-Assembling Nanotechnology: Manufacturing at the microscopic level.

- Intelligent Device Integration (IDI): Monitoring, managing and servicing of intelligent devices over the Internet.

- Integrated 3D Simulation and Modeling: Desktop supercomputers will revolutionize simulation and modeling, acting through microscope, telescope and time-machine operations to manage, view and tool a complete manufacturing system.

Perhaps a fortuitous result of the current recessionary environment is that the manufacturing decline is being recognized and addressed in new and innovative ways.

End Quote

Here is a link to an ealier discussion on the subject from American Machinist Magazine:

http://www.americanmachinist.com/304/News/Article/False/79569/

The major innovation we are concerned with at EfficientFactory is Intelligent Device Integration. This single innovation is not limited to manufacturing but will open up a wide range of applications. As devices have more intelligence built into them and get smarter, applications will be built to link all of these things together. The factory floor is a very confusing place, where disparate communications standards and protocols exist that don’t talk to one another.

This is the essence of distributed computing. Today the processing power is behind your screen in the box under the desk or on your lap. Soon the processing power will be all around you, fed through wires and waves – in the cloud.

Jim Pinto’s thoughts are covered in a monthly column in Automation World

After the IPO, and Implications for Firms That Want to Go There

The following link is to a presentation that ends with some rather chilling observations about the future of American Business. It features Dana Marshall, former President, Chairman and CEO of Applied Energetics Inc. speaking at the 2009 August meeting of the Missouri Venture Forum

It lasts about 30 minutes. The chilling stuff is in th last 10 minutes.

http://www.sbtv.com/MissouriVentureForum/8203

How will Startup Companies meet the needs of their investors?

Michigan Factory Makeover

Recently on NPR’s Marketplace there was an encouraging story about struggling automotive part manufacturers and there quest to fing new markets for their idled machines. They are going green. Listen or read about it at the Marketplace website.

http://marketplace.publicradio.org/display/web/2009/07/09/pm_michigan/

The piece comes off somewhat as a commercial for Michigan companies. Not to take anything away from them, Michigan has fallen on hard times, harder than most. The network of supply chains to the struggling automotive industry has a cascading effect of bad news. The suppliers a few links away are looking to fill up idled capacity.

How are they going to get there?

The tough business of auto parts manufacturing has been a good proving ground for cost containment and productivity increases. There are however new hurdles to overcome.

Flexibility is the key.

Many machine owners are taking one of two tacks. Ether they are engineering custom machines for custom applications or building in more flexibility required to create many different kinds of parts for many different applications.

The issue that automotive parts manufacture’s face is the cost of retooling. Here can be an immense capital expense with owning machine tools. That capital expense is analyzed against the expected life of the tool and the expected contract for the part. The big unknown is the forecast demand and the longevity of the part. These productive assets are required to make profits. If the tool is “too custom” and over engineered, the payback can be slim to none, or even a loss. Adding another facet dramatically lowers the cost. If the tool is FLEXIBLE in its application, the cost becomes far more palatable.

The cost to tool for a part can be very expensive. In order to compete on the global manufacturing field the automotive supply chain has invested a tremendous amount of capital to stay in the game. The leg up that Michigan may have, is that it has plenty of the machine tool infrastructure there hungry for new work.

Michigan’s factory in the NPR piece is more efficient than most by a long shot. The ultimate way to measure, is in the price quoted. Can a company make the same part as another thereby making more money? The longevity and volume of automotive parts is historically long. As these plants retool out of their niche in the automotive sector, they’ll find that, because of shorter production runs, making their machines and processes more flexible will help them be more successful in this new manufacturing environment.

Update on Boeing’s 787

Just a couple of weeks after the post on Boeing’s innovations in the supply chain, a new wrinkle was announced yesterday. Boeing is buying Vought Aerospace based in South Carolina. You can read or listen to it at NPR’s website; Boeing To Buy 787 Parts Plant In S.C.

It seems the strategy to outsource the parts for their new jetliner is more onerous than they thought. There is a lot to the decision in the story reported by NPR. Plenty of the reasons given are traditional, and undoubtedly have a major role in the decision.

I’ll go a little further than the NPR story does and postulate that another reason for the purchase is to develop a more inclusive culture between the two companies. What is of increasing importance in corporate culture is the exchange of information. Information exchange in a timely manner, in a common format, and that that is system compatible is increasingly important in today’s advanced manufacturing environment.

It’s tough to do throughout your own company let alone throughout your suppliers. It is however getting easier. Ultimately, the decision smells of “plan B”

Stay tuned, the bird will fly.